THE ULTIMATE IN PERSONALIZATION

To own a pair of Bontoni bespoke shoes is to know that no one else in the world has another pair like them.

Bontoni Su Misura, or bespoke, is the ultimate expression of individuality, style, quality and comfort. There is nothing quite as elegant as a gracefully executed pair of hand-made shoes. To own a pair of Bontoni Su Misura shoes is to know that no one else in the world has another pair like them. The process usually takes eight to ten months and about 55 working-hours. The entire process requires three separate, individual fittings.

The bespoke journey begins with an in-depth conversation between our master calzolaio, or shoemaker, and the client. They meet sometimes over lunch above the workshop.

Our calzolaio gathers information about the client’s history, preferences, passions, and personal style. The transformation of these details into a unique pair of Bontoni shoes then begins. Throughout the process, the calzolaio repeatedly consults with the client, helping him navigate the boundless options of materials, colors, patterns and types of construction.

Bontoni Su Misura, or bespoke, is the ultimate expression of individuality, style, quality and comfort. There is nothing quite as elegant as a gracefully executed pair of hand-made shoes. To own a pair of Bontoni Su Misura shoes is to know that no one else in the world has another pair like them. The process usually takes eight to ten months and about 55 working-hours. The entire process requires three separate, individual fittings.

The bespoke journey begins with an in-depth conversation between our master calzolaio, or shoemaker, and the client. They meet sometimes over lunch above the workshop. Our calzolaio gathers information about the client’s history, preferences, passions, and personal style. The transformation of these details into a unique pair of Bontoni shoes then begins. Throughout the process, the calzolaio repeatedly consults with the client, helping him navigate the boundless options of materials, colors, patterns and types of construction.

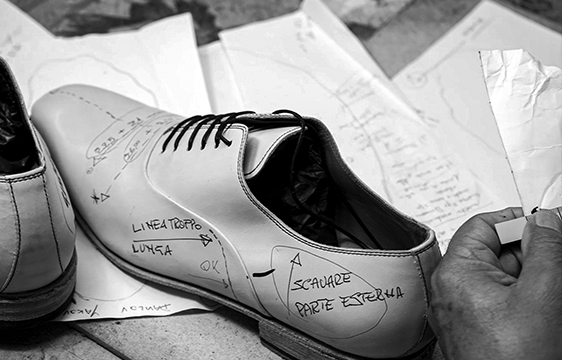

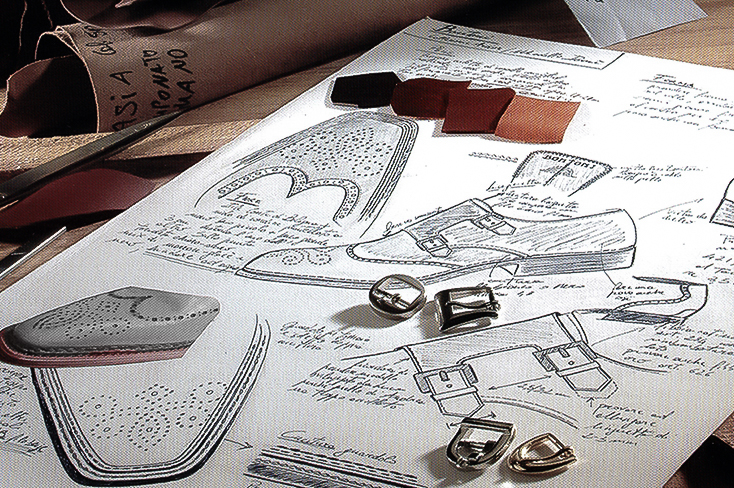

Once the initial choices have been selected and discussed, the calzolaio creates a detailed sketch of the model along with handwritten notes — regarding, for example, the type of toe box, the spacing of the eyelets and the thickness of the hand-stitch details. Unique lasts are made; hand-carved wooden replicas, or moulds, of the client’s feet. These require a series of precise measurements for each foot. Bontoni’s last maker painstakingly shapes and sculpts the last over a period of several

weeks. Each wood shaving and cut requires the same patience, steady hand, and attention to detail that Bruno employed when he made his violins. Once completed, the client’s lasts remain in our workshop to use for future pairs.

The pattern-maker works directly from the wooden last to outline the unique, desired pattern and create a paper template. The templates are then used to cut all the different leather sections of the shoes.

Once the initial choices have been selected and discussed, the calzolaio creates a detailed sketch of the model along with handwritten notes — regarding, for example, the type of toe box, the spacing of the eyelets and the thickness of the hand-stitch details. Unique lasts are made; hand-carved wooden replicas, or moulds, of the client’s feet. These require a series of precise measurements for each foot. Bontoni’s last maker painstakingly shapes and sculpts the last over a period of several weeks. Each wood shaving and cut requires the same patience, steady hand, and attention to detail that Bruno employed when he made his violins. Once completed, the client’s lasts remain in our workshop to use for future pairs.

The pattern-maker works directly from the wooden last to outline the unique, desired pattern and create a paper template. The templates are then used to cut all the different leather sections of the shoes. These leather sections are then hand sewn to create the upper. The upper is lined and reinforced with stiffeners before it is shaped on the last. The uppers are tacked to the last in order to achieve the proper contour. Typically, the process of “resting” on the last requires 4 to 5 weeks. After a few fittings, the sole and the uppers are then hand welted together.

As a final touch, the client’s name is hand-etched on the bottom of the sole. Shoes come with hand-sewn dust cover shoe bags. Clients may choose from a number of unique fabrics. Creating a unique Bontoni shoe takes time, but the result is a personal oggetto d’arte.

Every Su Misura client is encouraged to customize or “build” his own individual color. After the client has honed in on a color, we help him explore the numerous possibilities within that color itself. Together, we discuss the right mix of hues and tones, the degree of gloss, and the exact distribution; creating a map of these features for the upper.

As a final touch, the client’s name is hand-etched on the bottom of the sole. Shoes come with hand-sewn dust cover shoe bags. Clients may choose from a number of unique fabrics. Creating a unique Bontoni shoe takes time, but the result is a personal oggetto d’arte.